Electric-field assisted ion-exchange

The objective of this study is to investigate the potential application of a nonuniform electric field to enhance the generation of targeted ion diffusion patterns during the ion exchange process. The work is organized into two main sections: the experimental section and the modeling section.

1. Experimental section

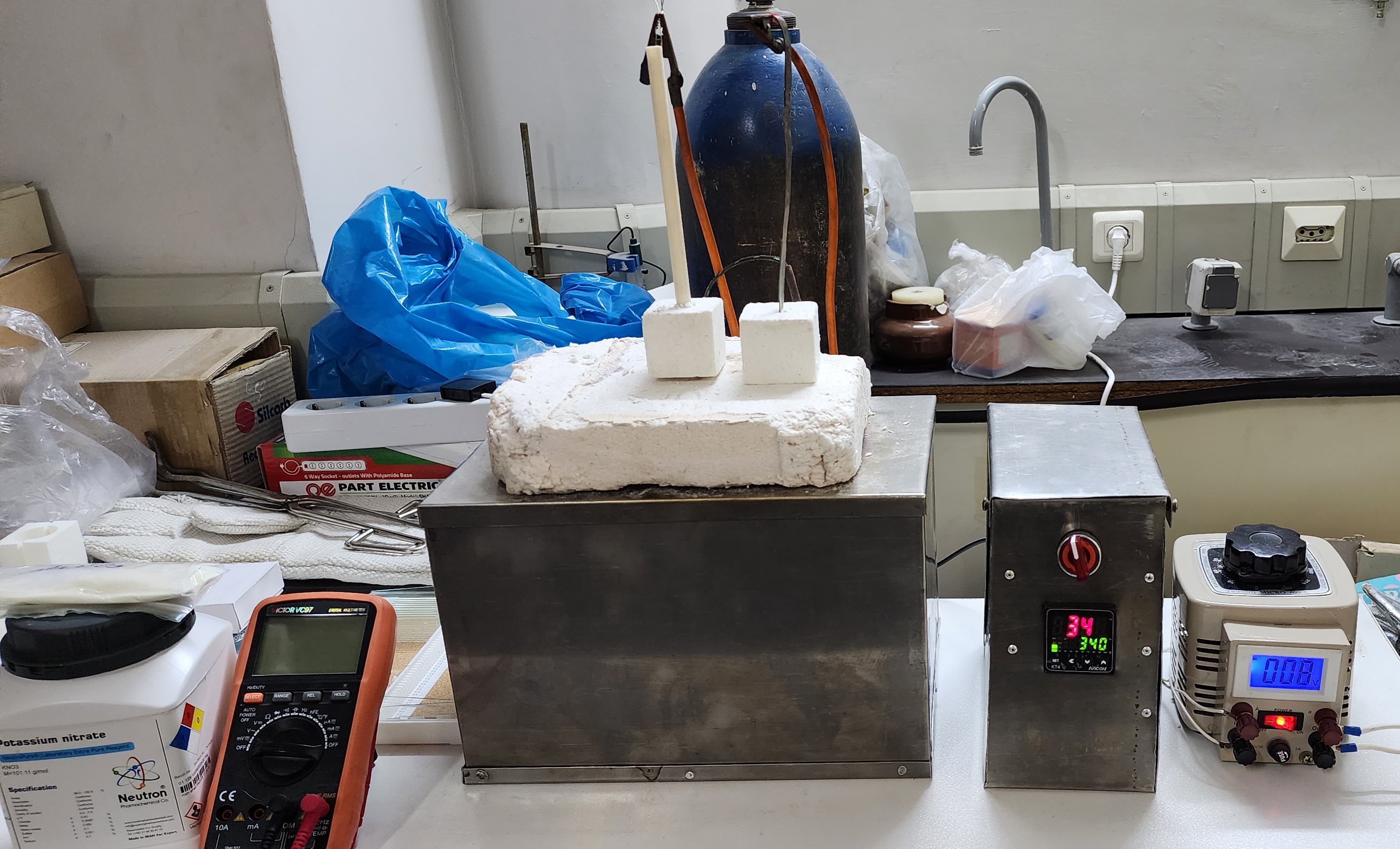

Diverse samples under varied conditions were meticulously prepared using a custom-designed experimental setup tailored for electric field ion exchange. Figure 2 illustrates this setup. The prepared samples underwent comprehensive analysis employing a diverse range of techniques, including EDS-Line, variable angle spectroscopic ellipsometry (VASE), Vickers hardness measurements, indentation toughness calculations, and bending strength testing.

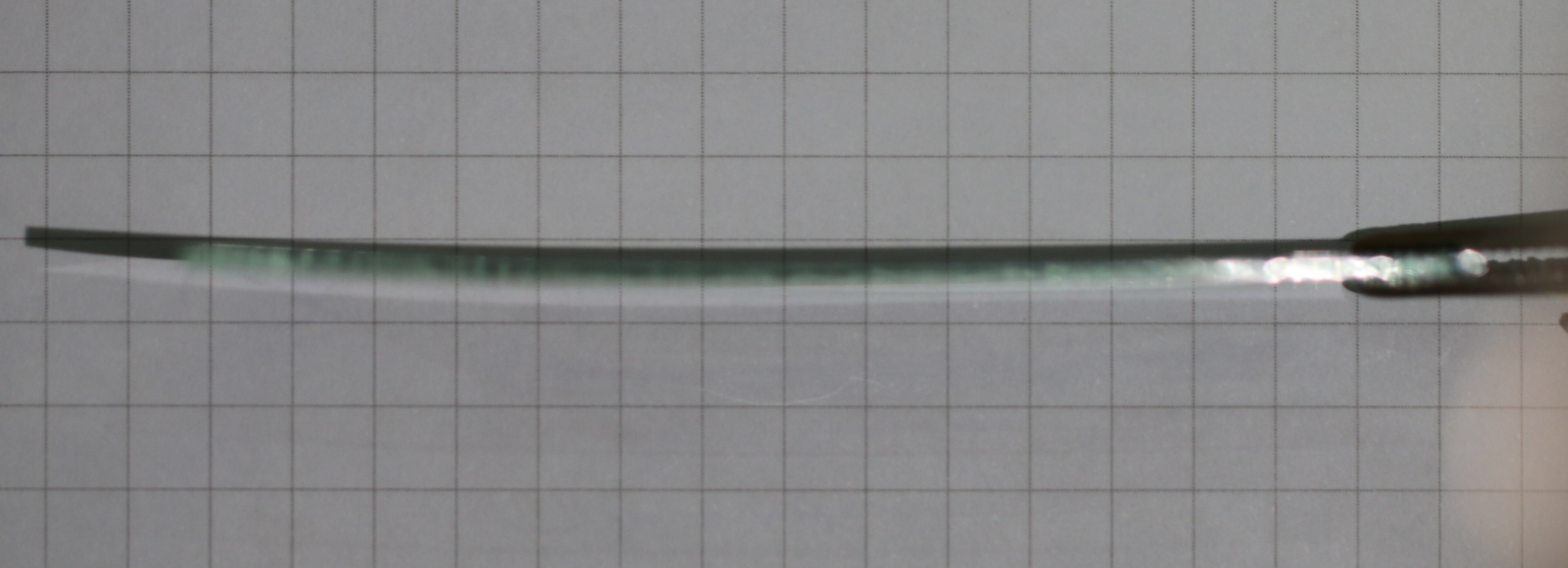

This study has yielded noteworthy findings that hold potential for publication in academic journals. As an illustrative example, Figure 3 visually represents a glass article subjected to ion exchange solely on one side, resulting in a noticeable bending effect—likely attributed to the presence of compressive stress.

2. Modeling section

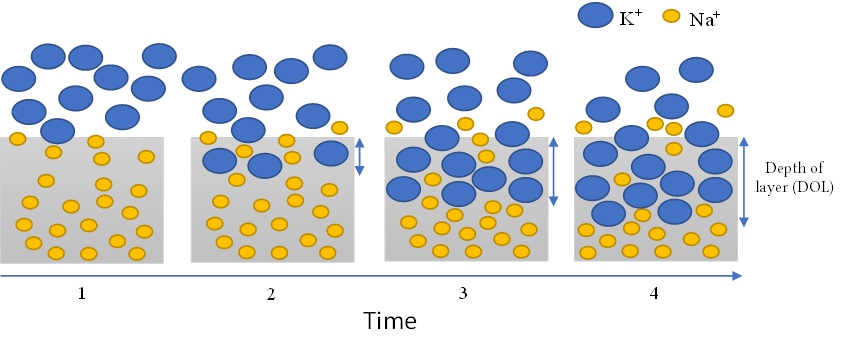

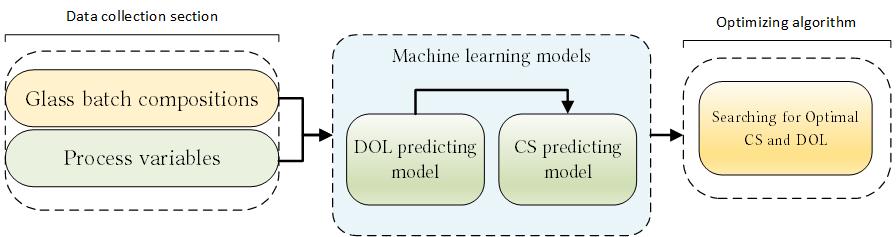

In this section of the study, we aimed to address a series of inquiries concerning the depth of layer (DOL) and compressive stress (CS). The research questions are outlined as follows:1- How does the depth of layer (DOL) change in relation to the chemical composition of the glass batch and various process parameters?

2- How does compressive stress (CS) fluctuate based on the chemical composition of the glass batch and different process parameters?

3- Which parameters exhibit the most significant influence on the depth of layer (DOL) and compressive stress (CS)?

4- Lastly, and notably, what constitutes the optimal glass batch composition and process parameters in terms of achieving the desired depth of layer (DOL) and compressive stress (CS)?

Publications:

[1] Banapour Ghaffari, O., B. Eftekhari Yekta, and M. Zakeri-Nasrabadi, Estimating “depth of layer” (DOL) in ion-exchanged glasses using explainable machine learning. Materialia, 2024. 33: p. 102027.DOI: https://doi.org/10.1016/J.MTLA.2024.102027[2] Banapour Ghaffari, O., B. Eftekhari Yekta, and M. Zakeri-Nasrabadi, Designing High-Performance Ion-Exchangeable Glasses with Multi-Objective Optimization and Machine Learning. Ceramics International, 2024.DOI: https://doi.org/10.1016/j.ceramint.2024.08.141.

Get In Touch

Feel free to reach out via email with any thoughts or suggestions that you believe could enhance my projects. Whether it's ideas for improvement or questions about the project itself, I am more than willing to engage in discussions and explore ways to collaborate for further development. Your input is valuable, and I appreciate the opportunity to discuss any aspects of the project that interest you.